PTC’s Are Solutions to Inrush Current

Inrush current, also known as startup or surge current, occurs when an electrical device is switched on, and it can exceed the device’s typical operating current significantly. This abrupt surge can strain the components of the circuit and can result in premature failure. Positive Temperature Coefficient devices have emerged as effective solutions for controlling inrush current in various applications. In this article, we will explore how they function as inrush current limiters and examine their advantages and disadvantages.

Looking For a PTC? View our PTC products, available now through our distributors!

How They Work

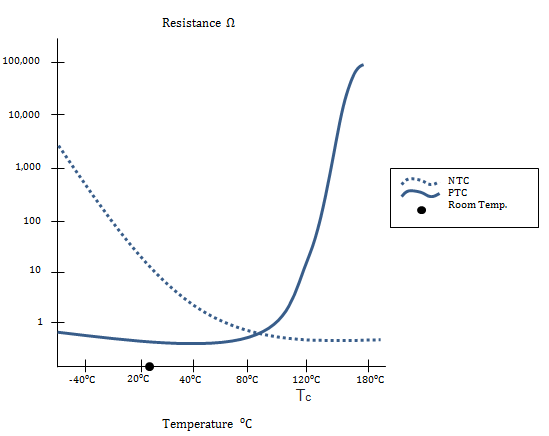

PTCs are a type of thermistor that becomes more resistant as they get hotter. They’re made from a special material that sharply increases its resistance when too much current flows through it so PTCs act like self-resetting fuses in a circuit. Here’s how they work as inrush current limiters:

- Initial High Resistance: When the circuit turns on, PTCs have high resistance, limiting the inrush current to a safe level. This prevents damage to sensitive components or devices.

- Self-Heating: As the current flows through the PTC, it creates heat due to resistance which causes their temperature to rise quickly.

- Resistance Transition: As the PTC’s temperature rises, its resistance increases dramatically. This change from low resistance to high resistance happens within milliseconds, effectively limiting the inrush current.

- Current Stabilization: Once the PTC reaches its high-resistance state, it stays that way until the current lowers or is turned off. As the circuit turns off, it cools down and returns to its low-resistance state, and allows normal current flow during operation.

Advantages of PTCs as Inrush Current Limiters

- Self-Resetting: PTCs reset automatically, which sets them apart from traditional fuses or resistors. They don’t need manual reset or replacement after an overcurrent event, making them reliable and cost-effective.

- Effective Inrush Current Limitation: PTCs effectively limit inrush currents, protecting sensitive components, reducing circuit stress, and extending device lifespan.

- Compact and Lightweight: PTCs are small and light, suitable for a wide range of applications, from consumer electronics to industrial equipment.

- Versatility: PTCs come in different sizes and resistance values, allowing customization to meet specific inrush current requirements in various applications.

Disadvantages of PTCs as Inrush Current Limiters

- Temperature Sensitivity: PTCs react by changes in temperature. If it gets really hot around them, they might not work as well or might give false signals.

- Voltage Limits: PTCs have particular voltage limits. If you go beyond those limits, the device can stop working. So, be careful when picking them for high-voltage situations.

- Not Great for Fast Changes: These devices may not be the best choice for situations where things change very quickly, like in high-frequency applications. They might not respond fast enough to handle sudden increases in current.

Conclusion

PTC devices excel at limiting inrush current, offering benefits such as automatic reset, effective current control, and suitability for diverse applications. However, they also have limitations, such as sensitivity to temperature changes and voltage restrictions. When you use them to control inrush current, it’s crucial to consider your specific application to ensure they perform well and safeguard your electrical equipment.

Ametherm thanks you for taking the time to read our Blog posts. If you have any questions, please contact us, or fill out the form below and we will respond right away.

Visit Our Distributors to See Availability of Our Inrush Current Limiters